Introduction of polishing and polishing technology of stainless steel screen

Stainless steel screen because the structure is complicated, so before making will choose mirror stainless steel tubes and stainless steel plate, so now most of the stainless steel screen polishing is directed at the welding parts, stainless steel screen polishing grinding process, because mainly through grinding machine for grinding wheel for processing, so it is pay attention to is the technical personnel's manual ability. In addition to the stainless steel screen polishing polishing process in addition to this kind of manual, if you need the overall polishing, then need more professional equipment, currently have a variety of electrochemical polishing, chemical polishing, mechanical polishing and so on very production.

1. Polishing:

Stainless steel screen polishing way is very many, if the surface polishing requirements are not high, most of the manufacturers will be through the way of mechanical polishing, after polishing, use the polishing machine into red hemp yarn wheel and coated with a layer of wax for polishing. Because the red hemp yarn wheel itself has less friction, coupled with a layer of wax on the surface, so you can press hard when polishing, do not worry about problems. Through this process, the welding place is basically polished.

2, grinding

Stainless steel screen in the polishing time need to be the welding part of the welding scar, residue grinding off, so that the whole face parallel behind the polishing effect will be better. The grinding method is mainly to use a grinding machine and various grinding wheels to rough grinding with a small mesh number, and then change to a large mesh number for meticulous grinding. It is important to pay attention to the grinding of these two parts, because the sandpaper has a very strong grinding ability, if the force may be the whole grinding place. So pay attention to strength, as long as the welding scar protruding part can be smooth.

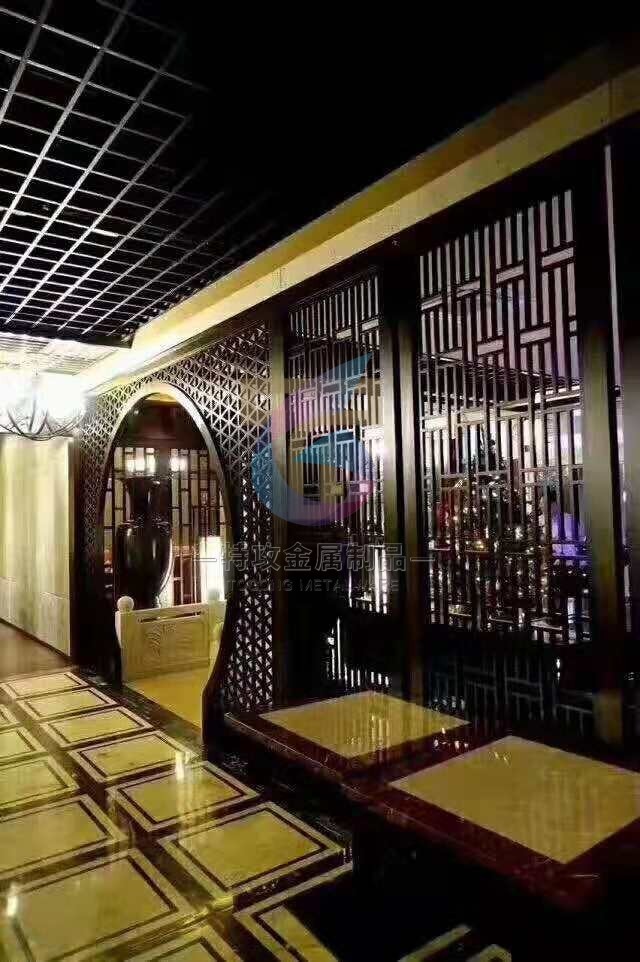

The polishing and polishing process of stainless steel screen mainly serves the stainless steel screen processed by welding, because the welding between stainless steel is through high temperature to melt two stainless steel together, so will produce welding scar and oxidized black iron, so the need for professional polishing tools to clean up these ugly welding scar. The distinction of high-quality stainless steel screen and common stainless steel screen, it is the actor or actress of polishing polishing craft how. After all, stainless steel screen for decorative requirements are relatively high, if these welding parts are not handled well, the overall beauty is a great impact.

Collection

Collection Share

Share Sitemap

Sitemap 中文

中文 English

English